Advertisement [ ? ]

Site Links

- Lease Calculator

- Advertise on 11,500+ pages

- My Car ongoing Review

- Members' Chat

- Cars For Sale

- Car Dealers

- Honda "Fit" Manual

- Hyperflex Bushings

- For Sale

- Fix your Car

- Car Manuals

- other manuals - Reference Materials

- DIY Repairs

- Articles

- Video

- Link with Us

- Search Help

- Code your Mac!

- Fly, race, anything R/C

- DIY repair guides

- Z-Seven

- Mechanic's Blog

- Free Files

Ceramic Brake Pads are HOT in the Friction Marketplace

It seems that almost every major aftermarket and original equipment brake supplier these days has some type of ceramic-based friction material in one of their product lines. Raybestos, one of the first aftermarket suppliers to offer a ceramic product, uses ceramics in their "Quiet Stop" line of premium disc brake pads. Akebono, an OEM supplier of ceramic pads also sells an aftermarket version of their product line. Bendix, who is best known for their "TitaniuMetallic" pads (which do not contain ceramics), also introduced a new line of ceramic pads a couple of years ago called "CF3." So is Bosch. Bosch Premium Pads have become Bosch Ceramic Pads. NAPA has their "Ceramix" line of brake pads that use a carbon ceramic material. ProMaster "Certanium" linings use a blend of ceramic and titanium fibers.

Why so much emphasis on ceramics? Because the aftermarket follows the original equipment market, and the domestic and Japanese OEMs have been using ceramic linings for years on many vehicles. One supplier estimated that some type of ceramic pad is now used on 50 to 60% of all new vehicles. If you count only those applications that use "real" ceramic pads (those where ceramics are a primary ingredient), the figure drops to about 40%, but is still a significant portion of the new vehicle fleet.

The only domestic vehicle manufacturer who has not used much ceramics is Chrysler. They have not used ceramic pads on their domestic-made cars and trucks, but have been using ceramics on their Mitsubishi-made vehicles. However, starting in 2004, Chrysler switched to ceramic pads on certain models.

That leaves the Europeans, who to date seem to prefer low-metallic friction materials that offer good performance, but tend to be noisy, dirty and wear quickly. A recent J.D. Powers survey in Germany revealed that many European car owners are not that happy with their brakes and would prefer quieter, cleaner, longer lasting brake linings. Some brake suppliers believe this signals an opportunity for ceramics in Europe, too.

THE CERAMIC AGE

Back in the 1980s most automakers were using semi-metallic pads on their front-wheel drive cars. Semi-metallic friction materials containing chopped steel fibers were, and still are, a popular choice for high-temperature, hard-use braking applications. But, because of their high steel content, semi-metallic compounds tend to be harsh, noisy and hard on rotors. Brake suppliers also developed a variety of nonasbestos organic (NAO) compounds, but NAOs are better suited for low-temperature applications and drum brakes. Something else was needed as an alternative to semi-mets.

Enter Akebono, an OEM brake supplier to most of the Japanese automakers. Akebono pioneered the development of ceramic-based friction materials back in 1985, and began to market their ceramic linings to a growing list of vehicle manufacturers in Asia and North America. Today, Akebono supplies most of the Japanese transplant manufacturers in the U.S as well as Ford (Taurus up to model year 2002, and the new Ford Explorer), GM trucks and Saturn. Akebono also has an aftermarket product line that is marketed under the ProACT banner (ACT stands for Akebono Ceramic Technology).

According to Bill Hilbrandt, vice president of research and development at Akebono, ceramic materials are a good choice for brake linings because they have stable and predictable friction characteristics, more so than most semi-metallic materials. Ceramics provide a consistent pedal feel that is the same whether the pads are hot or cold because the coefficient of friction does not drop off as quickly as semi-metallics. NVH (noise, vibration & harshness) is also less with ceramics, so the brakes are significantly quieter.

Ceramic compounds can be very complex and may use 18 to 20 different ingredients in a formula, including various fillers and lubricants that are added to help dampen vibrations and noise. A typical semi-metallic compound, by comparison, might contain only eight or nine ingredients.

Though semi-metallic linings generally provide better wear at higher temperatures, ceramics do just as well, if not better, at lower temperatures for the average driver. Consequently, pad life is often improved.

Low dust is another desirable characteristic of the material. The color of the material is a light gray so it is less visible on wheels (unlike some NAO pad materials that produce a dark brown or black dust that clings to wheels).

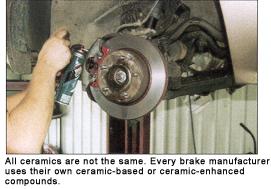

One very important point that Hilbrandt stressed is that all ceramics are not the same. Every brake manufacturer uses their own ceramic-based or ceramic-enhanced compounds. The type of ceramics used, the particle size, distribution, hardness and other ingredients that go into a ceramic type of friction material can all vary, even from one vehicle application to another. So ceramics should not be stereotyped or viewed as some type of generic product. Akebono Euro Ceramic Brake Pads, for example, are formulated specifically for European cars.

There is also disagreement over what should and should not be called a ceramic. Ceramic materials include a variety of substances including potassium titanate fibers as well as clay fillers. Many brake manufacturers use clay filler in certain friction linings, but do not call their product a ceramic lining. Others do. Consequently, the type of ceramic compounds used in a brake supplier's ceramic product line may vary significantly from those used by another brake supplier, along with the performance characteristics of their linings.

The actual amount of ceramic that is used in a friction material can also vary a great deal from one brake supplier to another. None of the manufacturers we interviewed for this article would revel the exact ceramic content of their linings. But several did made it very clear that the ceramic content can vary from a few percent to a significant percentage. What is really important is how the ceramic that is used affects brake performance.

Many products today are marketed under the ceramic banner because it is a hot buzzword. So, it is not surprising that most brake suppliers are now offering some type of ceramic material in their product lines.

AFTERMARKET CERAMIC BRAKE PADS

The main reason why the aftermarket got into ceramic friction materials is because the OEMs were using it. In the 1990s, a growing number of OEMs were using ceramic-based pads. Sooner or later the aftermarket had to follow suit and offer their own ceramic-based friction materials. In 1999, Raybestos announced the availability of their own "revolutionary" new brake friction formulation made from ceramic ingredients. The new product, which took three years to develop, was called "Quiet Stop."

Jerry Forystek of Raybestos said ceramics is still a big story, but that many people do not really understand the differences in ceramic compounds. "The real issue today is composition. How much ceramic is really in a pad and what does it actually do? The bottom line is how the pads perform on the vehicle. Our pads perform very well.

"The main advantages our product offer are reduced noise and dust, excellent wear characteristics and good fade resistance. Before we went to ceramics, we could never get the same kind of low noise levels, low dust and longer wear with other materials."

Forystek said ceramics are more expensive to manufacture and cost more, but the same is true of most other premium friction materials. You get what you pay for.

He also said that ceramics perform well in a wide variety of applications, but for some applications other materials work just as well or better. It depends on the vehicle platform and the type of driving. "That is why we use a best fit philosophy when choosing a particular friction compound for a given vehicle application."

CERAMIC-ENHANCED

Last year, ProMaster of Somerdale, NJ, introduced its new line of ceramic-enhanced "Certanium" disc brake pads. Marketed as an ultra-premium product, the new friction material combines the heat-dissipating properties of titanium with the strength of ceramic. The result is a product that provides high braking torque, fade-free operation, moderate and consistent pedal pressure, excellent heat recovery, elimination of brake squeal, reduced dusting, long life and is rotor-friendly. In short, it is a better product that performs better and lasts longer.

The only major brake supplier who is not pushing a "ceramic" branded product these days is Wagner. But according to Peter Murnen, manager of friction products, Wagner has been using various ceramic compounds for several years in some "ThermoQuiet" pads. The ThermoQuiet line also includes semi-metallic and nonasbestos nonmetallic (NANM) materials, too. It all depends on the application.

"Before we choose a friction material for a particular application, we first look at what the OEM used on that vehicle. Then we pick a material that closely mirrors their formulation. If the OEM material is a ceramic, we will use a ceramic."

Murnen said Wagner's philosophy is to use friction materials that closely match OEM materials and provide great performance. He also said a more important buzzword today is NVH (Noise, Vibration & Harshness), especially as an OEM brake supplier. There is a huge amount of emphasis put into tweaking friction formulas to minimize NVH, and this carries over into their aftermarket product lines, too.

BRAKE PAD REGULATIONS

Other factors that are having an impact on the type of friction materials that are being installed today include the new FMVSS135 standards that 2001 model year cars and 2003 model year trucks have to meet. FMVSS135 is a minimum braking performance standard by the National Highway Traffic & Safety Administration. It is a tougher standard than the former FMVSS105 rules, which has forced the automakers to upgrade the brakes on some vehicle models so they can meet the new stopping requirements.

One part of the new rule requires vehicles to stop within the same distance under the old FMVSS105 rule, but with 25% less pedal effort. To meet this specification, some manufacturers have had to switch to more aggressive linings. This, in turn, means the aftermarket has to offer replacement linings that equal the performance of the OEM linings. That is one of the driving forces behind the "application specific" trend in replacement linings.

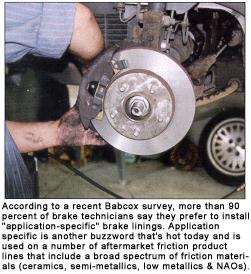

According to a recent Babcox survey, more than 90 percent of brake technicians say they prefer to install "application-specific" brake linings.

Application specific is another buzzword that is hot today and is used on a number of aftermarket friction product lines that include a broad spectrum of friction materials (ceramics, semi-metallics, low-metallics & NAOs). Application specific means the friction material has been carefully chosen to match the braking requirements of a particular vehicle platform. If we are talking about a ceramic-only product line, it will typically contain a number of different ceramic formulas instead of a single material.

ROTOR FINISH

An often-overlooked factor that can have a significant impact on the performance of any type of friction material is rotor finish. Bruce Prince of Pro-Cut International, a manufacturer of on-car brake lathes, said the strongest argument today for a good rotor finish is to minimize noise. The higher the quality of the rotor finish, the less noise the pads will make, and that includes any type of pads, not just semi-metallics.

"If someone installs an aggressive set of pads on a rotor with a poor finish, the pads will be noisy. If the same set of pads are installed on a rotor with a much smoother finish, you will not get the noise and you will not have comeback problems because of noise complaints."

Prince said most brand new rotors have a high quality finish that typically measures 20 to 25 microinches RA (roughness average). He said the Pro-Cut on-car lathe can produce a rotor finish that consistently measures 20 to 45 RA, which is usually better than what you get with many bench lathes. The main advantage of cutting rotors in place, though, is that it eliminates runout which can cause brake pedal pulsations and uneven rotor wear.

GOOD AS ORIGINAL EQUIPMENT BRAKE PADS?

Regardless of what type of friction material is used in a set of pads or shoes, the brakes must provide safe, reliable stopping power. Ideally, a set of aftermarket replacement linings will perform the same as or better than the OEM linings. Most do, and the brake manufacturers do extensive laboratory and field testing to assure that they do.

Jim Lawrence of the Brake Manufacturers Council (BMC) said their "Brake Effectiveness Evaluation Procedure" (BEEP) is one way brake suppliers are making sure their aftermarket products meet essentially the same requirements as the OEM linings. The BEEP test uses a single-end brake dynamometer to measure the friction characteristics, fade resistance and recovery curve of brake linings or specific vehicle platforms. Currently, the test procedure covers about 30 to 40% of the vehicle applications that are on the road. The goal is to develop test procedures for about 70% of the vehicle platforms, a process that takes a great deal of time and engineering effort to measure and calibrate specific vehicle applications.

"By mid-year, we expect to see the BEEP logo being used by some brake suppliers on their packaging. Most of our members are using the procedure now, so it is only a matter of time until they start to market it on their products," said Lawrence.

Raybestos "D3EA" (Dual Dynamometer Differential Effectiveness Analysis) certification program is a similar concept, but uses an independent test lab and a dual end (front and rear) brake dyno to evaluate aftermarket brake linings.

PREMIUM BRAKE PADS

In recent years, most aftermarket brake suppliers have also introduced new or upgraded premium or even "ultra-premium" product lines that feature their best lining materials. Some of these new lines are targeted at SUV/LT market, which can be very demanding on brakes.

Premium friction materials typically provide the best combination of stopping power, fade resistance, noise and wear. They also command a higher price, which more consumers are willing to pay on late-model, luxury-laden cars and light trucks.

Most premium pads also incorporate such features as chamfers, slots and special shims (integrally molded or stainless steel) to control noise and vibrations. Some are also "preburnished" to eliminate many of the problems that can occur if the pads are not broken in properly.

Adapted from an article written by Larry Carley for Brake & Front End magazine

Back to Brake | Back to Info Main Page

Total messages: 0